What Are Blind Flanges?

Blind flanges are like the stoppers for pipes. Imagine you have a water hose, and at the end, instead of water coming out, there’s a solid steel piece that covers it entirely. That’s a blind flange! It’s like a big steel lid with no hole in the middle.

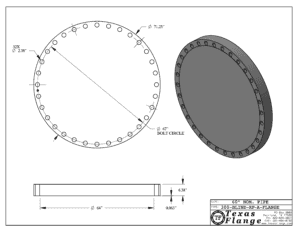

Image source:Texas Flange

How Are Blind Flanges Used?

Blind flanges have some cool jobs to do:

- Testing Pipe Pressure: Imagine you want to check how strong a pipe is without water or gas escaping. You can put a blind flange on the end to seal it off and safely test the pipe’s strength.

- Creating Access Points: Sometimes, you need to get inside a pipe for maintenance or checkup. A blind flange can be removed like a lid to give you access to the inside.

- Temporary Sealing: When a part of the pipe needs fixing, you can put a blind flange there temporarily to stop anything from flowing through until the fix is done.

- Long-Term Sealing: When a pipe isn’t needed anymore, a blind flange can be used to permanently seal it off and make sure nothing leaks in or out.

Construction and Customization

Now, let’s talk about how blind flanges are built and how you can customize them:

Construction: Blind flanges are typically bolted in place rather than welded. This design allows for easier access when needed for pipe system upkeep, inspection, or to accommodate future expansion. To ensure a tight seal, a gasket is often used. The gasket fills the space between the flange faces, preventing leaks of liquids or gases.

Blind flanges vary in constitution; however, they generally require minimal machining compared to other flanges. Their solid design and lack of bore make them relatively weighty compared to options with bores.

Customization: Blind flanges can be customized to suit specific needs. Some common alterations include the addition of NPT (National Pipe Thread) threads in the center or custom bore holes. These customizations allow blind flanges to serve various purposes, such as functioning as slip-on flanges without hubs.

For higher pressure applications, some blind flanges can be furnished with high hubs. For instance, most API 6BX blinds have high hubs as a requirement.

Different Types of Blind Flanges

Blind flanges come in different styles:

1. Raised Face (RF) Blind Flanges: These are the most common. They have a raised area on the flat surface that helps keep things sealed tight. They’re great for pipes that don’t have too much pressure.

2. Ring Type Joint (RTJ) Blind Flanges: These are super strong and used in high-pressure situations. They have a groove that holds a metal gasket in place to keep everything sealed up tight.

3. Flat Face (FF) Blind Flanges: These are smooth and flat on the surface. They’re used when you need a simple and clean seal for low-pressure pipes.

4. High Hubbed (HH) Blind Flanges: These are heavy-duty flanges used for high-pressure pipes, like those carrying steam or gas. They are usually tapped to hold pressure gauges or instruments to test the internal material..

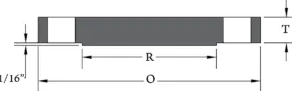

Image source:Texas Flange

Image source:Texas Flange

Material Required for Blind Flange

The choice of material for blind flanges depends on the specific requirements of the project. Common materials used for blind flanges include:

- Carbon Steel: Used for its strength and durability.

- Stainless Steel: Known for its resistance to corrosion.

- Chrome Alloys: Selected for their high-temperature resistance.

- Aluminium: Chosen for lightweight applications.

- Hastelloy: Preferred for its corrosion resistance.

- Inconel and Incolloy: Used in high-temperature and corrosive environments.

- Monel and Copper Alloys: Known for their resistance to seawater.

- Duplex and Titanium: Utilized in various specialized applications.

Common Questions About Blind Flanges

1. What is a blind flange?

A blind flange is like a steel lid with no hole in the middle, and it’s used to stop the flow of material in pipes.

2. When should I use a flat face blind flange?

Use flat face blind flanges when you need to seal a pipe and want a smooth surface and plan to use a full face gasket..

3. What are the benefits of raised face blind flanges?

Raised face blind flanges are preferred for higher-pressure applications due to their raised face which allows for the pressure created by the nuts and bolts to be compressed over a smaller space increasing the PSI with the same torque.

4. Can blind flanges be customized for specific jobs?

Yes, blind flanges can be customized with features like NPT threads and custom bore holes to suit specific needs.

5. What materials are used for making blind flanges?

Blind flanges can be made from different materials like steel, stainless steel, and more, depending on what’s needed.

6. Can blind flanges handle high pressure in pipes?

Blind flanges are governed by the same pressure/temperature charts in the ANSI/ASME specs that govern the other flanges. They can handle what is listed there and we can always help you find the right flange for the pressure requirements if you don’t have the specifications available.

7. How do I pick the right blind flange for my project?

The choice depends on your project’s needs, like how much pressure the pipe has and what materials you need. You can ask experts for help.

8. Are new blind flanges different from old ones?

Yes, new blind flanges are more versatile and don’t have the recesses that can be found on used ones. They can be used in many different situations, but avoid using blind flanges that have been used for pressure testing on new construction.

9. Do you offer blind flanges with threads?

Yes, some blind flanges can have threads for specific jobs. An example of how these are called out is: 4”150# RF Blind with 1” NPT tap A105.

10. Where are blind flanges used most often?

Blind flanges are used when you want to block a pipe for various reasons, like adding new flow controls or capping a line that is not currently being used..

In Conclusion

Blind flanges might look simple, but they play a big part in keeping pipes systems operating correctly. Whether it’s for a quick fix or a long-term seal, blind flanges help make sure everything flows smoothly in the world of pipes and industrial processes. If you require more information visit texasflange.com or https://en.wikipedia.org/wiki/Flange