Aluminum flanges are a practical choice in specific industrial applications. They are crafted from lightweight aluminum metal and offer unique advantages. We’ll explore these benefits and scenarios where aluminum flanges make sense.

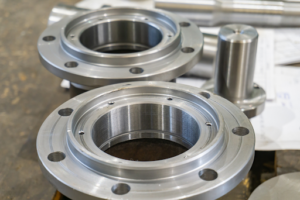

Image Source: Texas Flange

Advantages of Aluminum Flanges

Aluminum flanges have several strengths that make them a useful option:

1. Lightweight Design

Aluminum flanges are notably lighter compared to their steel counterparts. This quality helps reduce the overall weight of a system, which can be important in certain applications.

2. Cost-Effective

These flanges are budget-friendly due to lower material and production costs. They can be a wise choice for projects where expenses are a significant concern.

3. Efficiency

Aluminum flanges are quick to produce, making projects more time-efficient. This efficiency can minimize downtime and improve overall timelines.

4. Custom Sizing

They can be manufactured in various sizes, tailored to specific needs. This flexibility allows aluminum flanges to adapt to a wide range of industrial systems.

Types of Aluminum Flanges

Image Source: Texas Flange

Aluminum flanges come in different forms, each suited to particular requirements:

Low-Pressure Aluminum Threaded Pipe Flanges

Ideal for low-pressure applications where lightweight and corrosion resistance are essential.

Medium-Pressure Aluminum Threaded Pipe Fittings

Suitable for medium-pressure situations, offering a balance between strength and weight.

High-Pressure Aluminum Threaded Pipe Fittings

Designed for systems requiring high-pressure tolerance.

Aluminum Unthreaded Pipe Flanges

Cost-effective and lightweight, making them suitable for low-pressure scenarios.

Standard-Wall and Thin-Wall Aluminum Unthreaded Pipe Fittings

Available in various thicknesses, offering options for different levels of strength.

Durability and Sustainability

Aluminum is known for its strength-to-weight ratio and ease of recycling. Additionally, it naturally resists corrosion due to the protective aluminum oxide layer on its surface, within a specific pH range.

Image Source: Texas Flange

Frequently Asked Questions (FAQs)

- What are Aluminum flanges, and how are they used in industrial applications?

Aluminum flanges are components used to connect pipes, valves, and pumps in various industrial systems. They are employed in piping systems for their lightweight and corrosion-resistant properties.

- What advantages do Aluminum flanges offer compared to other materials?

Aluminum flanges are known for their lightweight design, cost-effectiveness, quick production, and custom sizing capabilities. They are efficient and adaptable to different project requirements.

- In which situations is it recommended to use Aluminum flanges?

Aluminum flanges are ideal for low-pressure systems, cost-conscious projects, and applications where weight reduction is a priority. They are also suitable when a quick production turnaround is necessary.

- What types of Aluminum flanges are available, and how do they differ?

Aluminum flanges come in various types, including low-pressure, medium-pressure, and high-pressure threaded pipe fittings. Unthreaded flanges and different wall thickness options are also available to suit specific needs.

- Are there any limitations to using Aluminum flanges?

While aluminum flanges have their advantages, they may not be the best choice for applications exposed to highly corrosive materials or extreme environmental conditions, where other materials like stainless steel could be more suitable.

- How can one ensure the durability of Aluminum flanges in industrial settings?

Proper maintenance, regular inspection, and selecting a reputable aluminum flange manufacturer are essential steps to ensure durability and reliability in industrial applications.

- What is the sustainability aspect of Aluminum flanges?

Aluminum is a recyclable material with a high strength-to-weight ratio. It naturally resists corrosion within a specific pH range, making it environmentally friendly and durable when used correctly.

- What factors should be considered when choosing between Aluminum and other flange materials?

Key factors include weight requirements, cost considerations, project timelines, and the specific environmental conditions the flanges will be exposed to.

- Can Aluminum flanges be used in plumbing applications?

Aluminum flanges can be used in plumbing, but their suitability depends on the specific plumbing system’s requirements. In situations involving highly corrosive materials, other materials like stainless steel may be more appropriate.

- Are there any safety concerns associated with using Aluminum flanges?

When used correctly and maintained properly, aluminum flanges are safe. However, like any component in an industrial system, they should be regularly inspected for wear and tear to prevent potential issues.

- Are there any size limitations for Aluminum flanges?

Aluminum flanges can be manufactured in various sizes to match the requirements of different industrial applications. The choice of size depends on the specific needs of the project.

- What are the common industries that benefit from using Aluminum flanges?

Industries such as manufacturing, construction, and petrochemicals often benefit from the use of aluminum flanges due to their lightweight, cost-effective, and efficient properties.

- Can Aluminum flanges be used in high-temperature applications?

Aluminum flanges are generally not recommended for high-temperature applications because aluminum’s melting point is lower than some other materials like steel. In such cases, materials with higher heat resistance may be more suitable.

- How can one identify the right Aluminum flange for a specific project?

The choice of an Aluminum flange should align with project requirements, taking into account factors like pressure, temperature, weight, and cost. Consulting with experts and manufacturers can help in selecting the most suitable flange.

- Can Aluminum flanges be modified or repaired if needed?

Yes, Aluminum flanges can be modified or repaired through processes like re-machining or welding. The extent of the repair depends on the nature and severity of the issue. In some cases, replacement may be necessary.

Choosing Aluminum Flanges

To determine if Aluminum flanges are the right choice, consider factors like weight, cost, production efficiency, and environmental conditions. Aluminum flanges are practical in scenarios where these factors align with project requirements.

In conclusion, Aluminum flanges offer specific advantages in industrial applications. They are a pragmatic choice in the right circumstances, ensuring efficiency and cost-effectiveness.

If you require more information visit: texasflange.com or https://en.wikipedia.org/wiki/Flange