Decoding Flange Standards: A Comprehensive Guide to ASME B16.5 Aluminum Flange Specifications and Applications

In critical piping systems, precise flange specifications ensure safe, leak-free connections under pressure, temperature, and corrosive environments. Decoding ASME B16.5 standards for aluminum flanges bridges the gap between raw material selection and reliable system performance. This guide maps out what aluminum flanges are, how ASME B16.5 defines their dimensions and pressure-temperature ratings, which flange types comply, and where they excel across industries. You will learn the core properties of aluminum alloys like 6061-T6 and 5083-H112, compare flange types such as weld neck and slip-on, explore corrosion resistance mechanisms, uncover installation best practices, and assess sustainability impacts. By following these insights, engineers and procurement specialists can enhance system integrity, simplify specification compliance, and support long-term operational efficiency.

What Are Aluminum Flanges and Why Are They Essential in Piping Systems?

Aluminum flanges are precision-forged or machined rings that connect pipes, valves, pumps, and equipment through bolted joints, improving system modularity and serviceability. Their lightweight construction and compliance with standardized dimensions streamline installation and reduce structural load. For example, replacing steel flanges with aluminum counterparts in HVAC ductwork cuts weight by up to 60%, simplifying support structures and improving handling. Understanding aluminum flange fundamentals prepares us to explore their governing standard, ASME B16.5, which ensures interchangeability and safety across industries.

What Defines an Aluminum Flange?

An aluminum flange features a circular body with bolt holes and a sealing face, designed to mate flush against a gasket and opposing flange for leak-proof connections. Its body may include a raised face or full face to concentrate gasket compression and optimize sealing. The forging or casting process, followed by CNC machining, ensures consistent tolerances and surface finish, which is critical for meeting ASME B16.5 dimensional requirements.

What Are the Key Properties of Aluminum Flanges?

Aluminum flanges deliver three primary advantages:

- Lightweight Construction enhances handling and reduces support structure requirements.

- Corrosion Resistance through a stable aluminum oxide layer extends service life in marine and chemical environments.

- Thermal Conductivity enables rapid heat dissipation in high-temperature applications.

These attributes improve system performance while ensuring compatibility with ASME B16.5 standards, guiding the pressure-temperature ratings and material specifications that follow.

Aluminum Flanges: Properties and Applications

Aluminum flanges are favored in industrial and marine applications due to their lightweight nature and resistance to corrosion, especially in harsh environments. They are also electrically conductive and non-magnetic, making them suitable for applications where these properties are essential.

This source highlights the key properties of aluminum flanges, which are discussed in the article, such as lightweight construction and corrosion resistance.

Which Aluminum Alloys Are Commonly Used for Flange Manufacturing?

Manufacturers typically select aluminum alloys that balance strength, corrosion resistance, and machinability. The table below compares key alloys used in ASME B16.5 aluminum flanges:

Each alloy selection influences pressure-temperature limits under ASME B16.5, which we’ll examine next in the context of the standard’s scope.

Common Aluminum Flange Materials & Grades

Alloy 6061-T6 is a popular choice for aluminum flanges due to its balance of strength, weldability, and corrosion resistance. Alloy 5052 is known for its excellent saltwater corrosion resistance, making it suitable for marine applications.

This source provides information on the common aluminum alloys used in flange manufacturing, which is discussed in the article.

How Does ASME B16.5 Standard Apply to Aluminum Flanges?

ASME B16.5 governs the dimensions, pressure-temperature ratings, material specifications, and marking requirements for pipe flanges and flanged fittings from NPS ½ through NPS 24. By defining uniform tolerances and ratings, it ensures that aluminum flanges integrate seamlessly with components from multiple suppliers, enhancing safety, reliability, and maintenance efficiency.

ASME B16.5 Standard for Pipe Flanges

ASME B16.5 is a standard that specifies the dimensions, pressure-temperature ratings, materials, and testing requirements for flanges used in piping systems. It ensures interchangeability and safety across various industries.

This citation supports the article’s discussion of the ASME B16.5 standard, which governs the specifications for aluminum flanges.

What Is the Scope and Purpose of ASME B16.5 for Flanges?

ASME B16.5 specifies:

- Dimensions and Tolerances for flange outside diameter, bolt circle, and face thickness.

- Pressure Classes from 150 to 2500, with corresponding pressure-temperature rating tables.

- Material Requirements referencing ASTM B247 for aluminum alloy forgings.

This framework underpins safe flange performance across diverse temperatures and pressures, setting the stage for compliant aluminum flange production.

What Are the ASME B16.5 Pressure Classes for Aluminum Flanges?

ASME B16.5 assigns six pressure classes (150, 300, 600, 900, 1500, and 2500) each representing a maximum allowable working pressure at a given temperature. Class 150 flanges, for example, can handle up to 275 psi at ambient temperature, while Class 600 ratings exceed 740 psi. These classes guide engineers in selecting flanges that match system design pressures without over-sizing or under-rating.

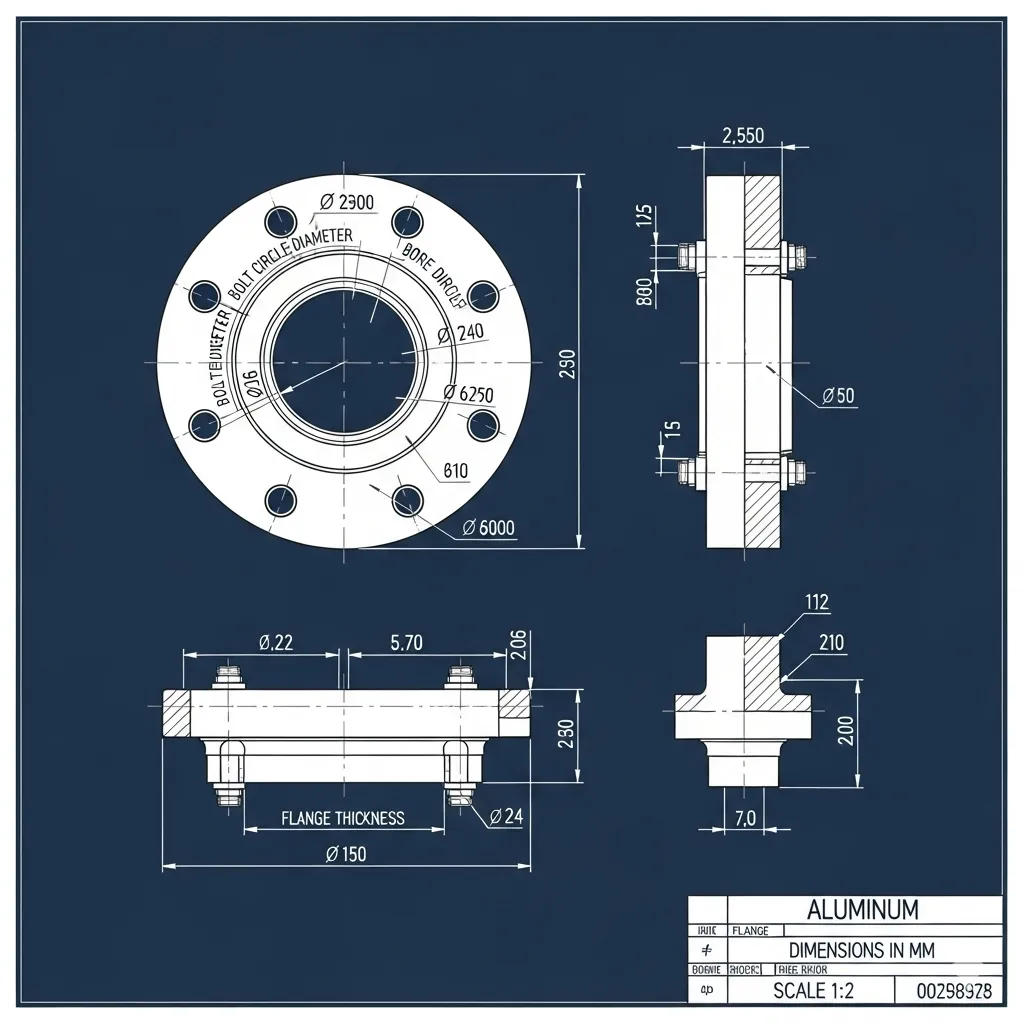

How Are ASME B16.5 Dimensional Standards Defined for Aluminum Flanges?

Dimensional standards in ASME B16.5 include critical parameters such as flange outside diameter, number and diameter of bolt holes, bolt circle diameter, and face thickness. Tolerances are specified to ±1/32 in. for most dimensions, ensuring consistent gasket compression and bolt fit. By machining to these tolerances, manufacturers guarantee interchangeability and uniform sealing performance.

What Material Specifications Does ASME B16.5 Require for Aluminum Alloys?

For aluminum flanges, ASME B16.5 references ASTM B247, which mandates chemical composition, mechanical properties, and forging quality. It requires certification of alloy temper and traceability of heat treatment processes. Compliance with ASTM B247 ensures that the selected aluminum alloy grades deliver the strength and corrosion resistance necessary for rated service conditions.

What Are the Types of Aluminum Flanges Compliant with ASME B16.5?

ASME B16.5 defines six common flange types for aluminum piping systems: weld neck, slip-on, blind, threaded, lap joint, and socket weld. Each design balances ease of installation, cost, and pressure handling to meet specific application needs.

What Are Weld Neck Aluminum Flanges and Their Applications?

Weld neck flanges have a long tapered hub that supports high-stress bolted joints, guiding stress into the pipe wall and reducing fatigue. They are ideal for high-pressure and high-temperature systems such as steam lines and chemical reactors.

How Do Slip-On Aluminum Flanges Differ and Where Are They Used?

Slip-on flanges slide over the pipe and are fillet-welded both inside and outside, offering simplified alignment and reduced cost. They suit low-pressure HVAC, water treatment, and some chemical applications where pressure classes up to 300 are common.

What Are Blind Aluminum Flanges and Their Typical Uses?

Blind flanges lack a bore, sealing pipe ends or valve openings for system isolation and pressure testing. Their solid face design enhances strength and simplifies pressure-testing procedures in offshore platforms and pressure vessel connections.

What Are Threaded, Lap Joint, and Socket Weld Aluminum Flanges?

Threaded flanges engage with matching pipe threads for bolt-on assembly without welding, benefiting flammable or explosive environments. Lap joint flanges pair with a stub end to allow frequent disassembly, common in sanitary food-processing lines. Socket weld flanges fit into a recessed pipe socket and are fillet-welded for compact, leak-resistant joints in high-vibration applications.

How Are Pressure-Temperature Ratings Determined for ASME B16.5 Aluminum Flanges?

ASME B16.5 provides distinct pressure-temperature tables for each alloy and pressure class. These tables consider the material’s tensile strength reduction at elevated temperatures to assign safe working pressures.

Pressure-Temperature Ratings of Aluminum Alloy Flanges

ASME B31.3 Appendix L provides pressure and temperature ratings for forged aluminum flanges, including those made from 6061-T6 and 3003-H112 alloys. These ratings are essential for ensuring safe operation across different temperatures and pressures.

This source provides information on the pressure-temperature ratings for aluminum flanges, which is a key aspect of the article.

How Does ASME B16.5 Define Pressure-Temperature Ratings for Aluminum Alloys?

Ratings combine alloy-specific yield strength data with safety factors. For example, the Class 150 rating for 6061-T6 is 275 psi at 100°F, dropping to 100 psi at 400°F. Each class table accounts for temperature-induced strength loss, ensuring flanges operate safely across thermal cycles.

What Are the Pressure Ratings for Common Aluminum Alloys Like 6061-T6 and 5083-H112?

A quick alloy comparison shows:

This table illustrates how alloy choice impacts system pressure capacity, guiding designers to match alloy and class to fluid conditions.

Why Is Understanding Pressure-Temperature Ratings Critical for Flange Safety?

Selecting flanges with appropriate ratings prevents over-stress failures and leaks that can lead to downtime, environmental release, or personal injury. Designers must cross-reference operational temperatures with pressure classes to maintain safety margins throughout varying process conditions.

What Are the Corrosion Resistance Characteristics of Aluminum Flanges?

Aluminum’s natural oxide layer provides primary defense against corrosion, but environmental factors and galvanic coupling can challenge performance. Understanding corrosion types and prevention methods extends flange life and preserves system integrity.

What Types of Corrosion Affect Aluminum Flanges?

Common corrosion mechanisms include:

- Pitting Corrosion in chloride-rich environments, causing localized damage.

- Galvanic Corrosion when aluminum contacts dissimilar metals in the presence of an electrolyte.

- Crevice Corrosion under gaskets or overlapping surfaces where oxygen access is limited.

How Can Corrosion Be Prevented in Aluminum Flange Applications?

Preventive strategies include:

- Protective Coatings such as anodizing or epoxy linings to isolate aluminum from corrosive media.

- Cathodic Protection via sacrificial anodes or impressed current systems.

- Insulating Gaskets and Washers to separate aluminum from dissimilar metals.

Corrosion of Aluminum and Aluminum Alloys

Corrosion of aluminum flanges can be caused by moisture, chemicals, and contact with dissimilar metals. Protective coatings, such as epoxy, can help prevent corrosion by forming a barrier against corrosive agents.

This source supports the article’s discussion on corrosion resistance and prevention methods for aluminum flanges.

How Does Aluminum’s Oxide Layer Enhance Corrosion Resistance?

Aluminum spontaneously forms a stable Al₂O₃ film that seals the metal surface, slowing further oxidation. This passive layer self-heals when scratched, offering ongoing protection in neutral and mildly alkaline environments, which aligns with many ASME B16.5-rated fluid services.

Where Are ASME B16.5 Aluminum Flanges Commonly Used?

Aluminum flanges excel in applications requiring low weight, corrosion resistance, and standardized dimensions. Industries leverage these properties to improve performance and reduce operating costs.

Which Industries Rely on Aluminum Flanges?

Key sectors include:

- Aerospace structures and fuel systems

- Marine piping and offshore platforms

- HVAC ductwork and chilled water circuits

- Chemical processing and desalination plants

How Do Aluminum Flanges Benefit Marine and Aerospace Applications?

In marine environments, aluminum flanges resist saltwater corrosion, reducing maintenance in shipboard piping. In aerospace, weight savings translate to fuel efficiency and payload capacity increases, allowing engineers to support performance requirements without sacrificing structural integrity.

What Are the Advantages of Aluminum Flanges in HVAC and Chemical Processing?

Aluminum flanges improve thermal conductivity in HVAC systems, enhancing heat exchange efficiency. In chemical processing, their corrosion resistance lowers replacement frequency in corrosive media, ultimately cutting lifecycle costs and downtime.

How Do Aluminum Flanges Compare to Other Materials Under ASME B16.5 Standards?

Comparative analysis clarifies when aluminum offers the best balance of properties versus steel and stainless options.

What Are the Differences Between Aluminum and Stainless Steel Flanges?

How Do Aluminum Flanges Compare to Carbon Steel Flanges?

Carbon steel flanges offer high strength and heat tolerance but require coatings to prevent rust. Aluminum’s natural passivation removes the need for coatings in many marine and HVAC applications, though it cannot match steel’s high-temperature capacity.

When Should Aluminum Flanges Be Preferred Over Other Materials?

Choose aluminum flanges when weight reduction, moderate corrosion resistance, and standardized pressure-temperature ratings meet system demands without requiring the extreme strength or high-temperature tolerance of steel variants.

What Are Best Practices for Installing and Maintaining ASME B16.5 Aluminum Flanges?

Correct installation and proactive maintenance safeguard flange integrity, minimize leak risks, and extend service life.

How to Select the Right Gasket and Bolting for Aluminum Flange Joints?

Select non-galvanic gasket materials (e.g., PTFE, compressed fiber) and corrosion-resistant bolts (stainless steel or coated alloys) sized per ASME B16.5 bolt torque tables. Matching gasket hardness to flange face finish ensures even compression and reliable sealing.

What Are Recommended Bolt Torquing Procedures for Aluminum Flanges?

Apply torque in a star pattern, increasing in stages to reach the specified torque value—typically 25–30 ft-lb for Class 150 aluminum flanges. This method promotes uniform gasket compression and prevents flange distortion.

How to Prevent Galvanic Corrosion During Installation?

Insulate aluminum flanges from dissimilar metals using non-conductive washers, sleeves, and gaskets. Avoid direct contact with carbon steel bolts by using sleeves or selecting compatible hardware to maintain the oxide layer’s protective effect.

What Are Routine Inspection and Maintenance Guidelines?

Inspect bolting tension, flange face condition, and gasket integrity every six months in corrosive environments and annually elsewhere. Replace gaskets at first sign of compression set or corrosion and retorque bolts to maintain sealing pressure, ensuring long-term flange performance.

How Does Sustainability Impact the Use of Aluminum Flanges in Industry?

Sustainability considerations increasingly drive alloy selection and lifecycle planning for piping components, with aluminum offering distinct environmental advantages.

What Are the Environmental Benefits of Using Aluminum Flanges?

Aluminum flanges are highly recyclable—up to 90% of material can be reclaimed and reused with minimal energy input compared to primary production. This recyclability reduces carbon footprint and supports circular economy goals in manufacturing.

How Does Lightweight Aluminum Contribute to Energy Efficiency?

Every pound of weight saved in transportation and structural support lowers fuel consumption in mobile applications such as marine vessels and aerospace systems. Over large fleets, this translates into significant emissions reductions and cost savings.

What Are Industry Trends Toward Sustainable Flange Materials?

Emerging trends include increased use of recycled aluminum alloys, design optimization for material reduction, and integration of lifecycle assessment tools. These practices guide engineers toward specifying flanges that meet performance requirements while minimizing environmental impact.

Aluminum flanges that align with ASME B16.5 standards deliver a powerful combination of lightweight handling, corrosion resistance, and standardized interchangeability. By understanding alloy properties, dimensional requirements, pressure-temperature ratings, and installation best practices, engineers can enhance system reliability and sustainability. As industries continue to prioritize lightweight and recyclable materials, aluminum flanges will play an ever-expanding role in efficient, eco-friendly piping solutions.